Did you know the number one cause of early failures of lead-acid industrial batteries is sulfation? The build up of lead sulfate crystals eventually leads to loss of cranking power and longer forklift battery changing times.

Battery plates regularly get sulfated. When batteries discharge, the lead active material on the plate reacts with the sulfate from the electrolyte and forms a lead sulfate residue on the plates. This reaction drains the battery of all lead active material and sulfate from the electrolyte remaining causing the battery to be fully discharged. After the battery is fully discharged like this, a recharge must commence as soon as possible. The recharge process consists of the lead sulfate residue converting back into the lead active material and the remaining sulfate is returned to the electrolytes.

What Does Forklift battery sulfate Mean?

Sulfate is considered to be a flexible variable to the solution of the specific gravity. For example, when the sulfate is removed from the electrolyte the specific gravity is reduced but the specific gravity increases when the sulfate is returned to the electrolyte instead. Due to the flexibility of sulfate, a hydrometer can be used to determine exactly which state sulfate is currently in.

It is important to recharge a discharged battery as soon as possible because if a battery is left in a discharged state for too long, the lead sulfate will become hard and will have a very high resistance when recharge is attempted. This process leads to an unwanted and unusable sulfated battery. The battery becomes unusable when the lead sulfate becomes so hard that normal recharging will not be able to break it down again. The state of the battery's charge is vitally important because it controls the current flow for most chargers. The battery voltage will rise until it levels out with the charger's regulated voltage, causing the charger to lower the output current. In the event when a sulfated battery attempts to be recharged, the sulfated battery will show a fake voltage amount that is greater than its actual voltage amount, which fools the charger’s voltage regulator into thinking it, has successfully recharged the sulfated battery to its full capacity. The charger will then lower its current output prematurely causing the sulfated battery to remain discharged and unusable.

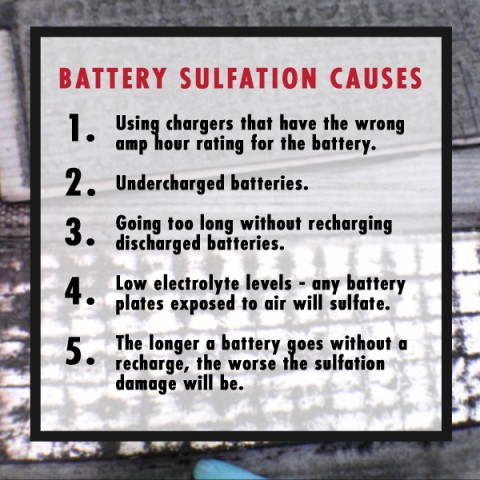

Issues that lead to sulfated Forklift batteries:

- Using chargers that have the wrong amp hour rating for the battery being attempted to recharge

- Undercharged batteries can also lead to sulfated batteries

- Discharged batteries can become sulfated if they go for too long without recharging

- Electrolyte levels are important because if they are too low, it will kill the lead acid batteries and expose the battery plates to the air causing them to build up sulfate immediately.

- Finally, the longer amount of time a discharged battery goes without a recharge, the greater the amount of sulfation damage will occur to the discharged battery.

Think you might have sulfated batteries? Feel free to contact Southern States Enterprises today! Southern States Enterprises offer a variety of high amperage and low voltage industrial chargers that are formulated to break down the difficult sulfation residue on a sulfated battery allowing you to get as much use out of batteries yet again.